Rompetrol Rafinare is close to finalizing the implementation of the first phase of Advanced Process Control (APC), a digital solution that will help improve the production activities of the Petromidia Refinery in Navodari. Amounting to an estimated cost of about USD 4 million, APC is a complex software for predictive control of units and operational flows, aiming to identify optimal conditions for increasing the capacity, product quality improvement, reducing energy consumption and more effective control of key parameters.

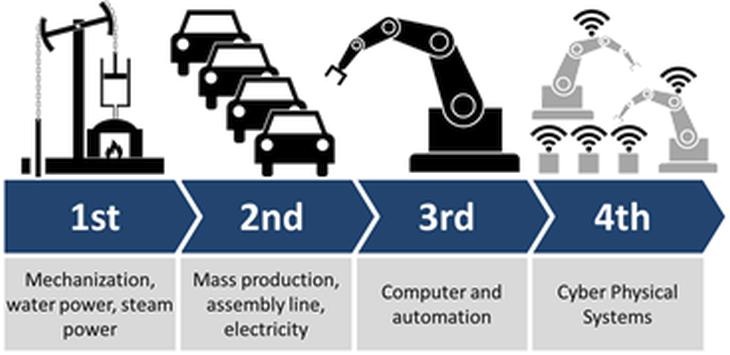

The Refinery is the largest production facility of this kind in Romania and one of the most modern in the Black Sea region. “It is an important step for Romanian crude oil processing business, alignment with international trends in the field, through the implementation and adoption of digital solutions, artificial intelligence to increase profitability, more rigorous control of the obtained products, and operational stability of the units and of the technological flows. All these aspects lead to the fourth industrial revolution – Industry 4.0, and Rompetrol continues to be a local pioneer by launching a comprehensive digital transformation program at the Petromidia Refinery in Navodari,” said Yedil Utekov, General Manager of Rompetrol Rafinare, in a press release.

APC is based on a thermodynamic and statistical model, which, along with a linear programming technique and an economic performance function, ensures a natural evolution of units’ operation – from manual setting of parameters (temperatures, flows, pressures) to setting desired characteristics for the obtained products (quality, processed raw material, other technical specifications, etc

Industrial revolutions and future view

).

The implementation of the digital solution began in 2017 as a pilot project at the Atmospheric and Vacuum Distillation Unit (DAV) – one of the most important units in the processing of crude oil that ensures the raw material for the rest of the installations from the refinery. The benefits generated by APC for this unit amounted to about USD 1.5 million/year, but also led to stability in operational activity.

The APC implementation program at the Refinery level has been divided into 4 major phases considering the complexity of technological flows, the end of 2020 being established as the deadline for completion of this project.