What is the added value of platforms, what categories and applications are there? FH professor Stefan Fink offers an insight into the business model of platform companies – including an in-depth look at the machine operators and manufacturers division.

The central building block of companies and solutions of the platform economy is the combination of two or more market participants using digital technology and structured data. This makes the business model of platform companies diametrically different from traditional organizations. Platforms act as intermediaries that both serve as a marketplace (“matchmaking”: intermediation between supply and demand and transaction processing) and enable completely new interactions and technologically innovative solutions through the digital connection of the participants.

Added value through platforms

In this way, platforms create three essential types of added value:

- Reduction of transaction costs: Cost reductions are achieved on one hand by simplified interactions via a common technical platform and on the other hand are also a result of the specific platform services. Typical transactions are the mediation between supply and demand, the provision of data or the automated processing of contract or payment processes. Platforms reduce transaction costs by standardizing communications and contract components, reducing coordination effort, and the coordinated ecosystem.

- Scale or network effects: Because supply and demand stimulate each other, the platform becomes (still) more attractive by each additional participant: The more participants sign up as providers of accommodation on Airbnb, for example, the more customers will consider the platform as an intermediary for overnight stays and ultimately make intermediation through Airbnb instead of a direct hotel booking. The increasing number of placements in turn makes the platform interesting for additional providers of accommodation: a self-reinforcing network effect is created.

- Generation of individual customer benefits: Platforms enable transactions that would not occur at all without their use or existence and can thus serve undiscovered or completely new customer needs. The capacity for data processing, analysis and “intelligence” of the platform form the basis of specific services and thus only allow the satisfaction of certain customer needs. As a result, they enable additional (digital) services, new business models or operational efficiency improvements.

Although the roots of the platform economy lie in the B2C sector, this is increasingly becoming a major competitive factor for business customers (B2B), especially in the industrial sector.

Platform categories

In the industrial sector, two types of platforms are relevant:

- Digital marketplaces for industrial goods and services: On digital marketplaces, physical goods from the industrial sector are offered for sale and transactions are processed. Among the best known are Mercateo, SAP Ariba, Wucato (subsidiary of the Würth Group) and the online shop for tools and technical components Zamro. Currently, in the area of digital marketplaces, a massive expansion of transaction volumes in the B2B sector, an increasing number of marketplaces and the displacement of traditional forms of purchasing can be observed.

- IoT Platforms: IoT platforms provide the digital infrastructure and standards for connecting the customer to the cloud. At the same time, they offer both their own and third-party services, offer them on an online marketplace and develop new opportunities for customer loyalty or completely new business models.

Combined with IoT technology, digital platforms provide the ability to connect the physical and virtual worlds, connect machines and assets, and use digital services with economies of scale.

IoT Platforms: Ways of Expression, Parameters, and Application Examples

IoT platforms offer and control a data-centric system of complementary products and services. In best-practice examples of production, the machines are networked with each other via sensors and connected to the digital platform. The machine data is transferred to the platform on which the data is merged, analyzed, evaluated and used. The use is carried out via applications provided by the platform operator, which can also be developed and introduced by external service providers. External service providers can be app developers, machine manufacturers and interface developers, as well as system integrators or software developers.

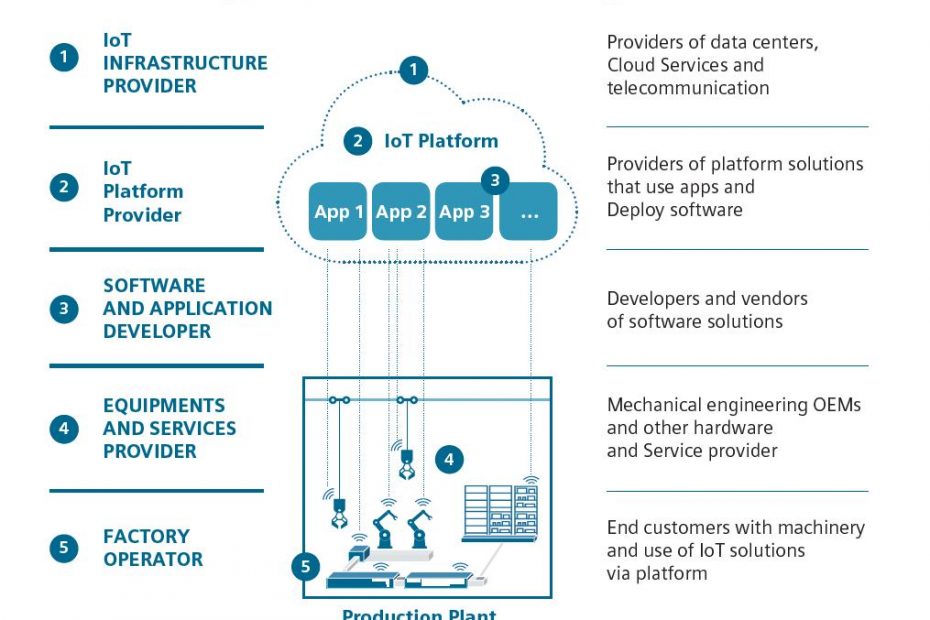

Users of digital IoT platforms are machine and component manufacturers on the one hand, but also manufacturing companies that use the machines on the other hand. Success factors are open and light, ideally standardized accesses for the participating partner companies as well as necessary compatibility between the system components. The figure above shows the five levels of a digital IoT platform and the actors involved at each level.

This figure shows the five levels of an IoT digital platform and the players involved in each level.

Perspectives and challenges for machine operators and manufacturers

The advantages of connecting to an IoT platform depend on the initial situation and business model of the respective company. Depending on whether the machine operator or manufacturer is involved, different benefits and benefits can be identified. At the same time, IoT platform connectivity is also a major challenge for a company, as this significant process and strategy change requires a sometimes very strong organizational rethink. The key opportunities and challenges are as follows:

Machine operators

The most important opportunities and benefits for machine operators lie in the following areas, among others:

- Savings on maintenance costs

- Reduction of downtime and decision-making times

- Quality improvement in the products produced

- Automation of supply chains

- Use your own data as a kind of currency for access to the platform.

In order to be able to take advantage of the potential for opportunities, the following questions must be answered in the company:

- Is there a willingness to share company-owned data in the ecosystem of a digital platform with others, i.e. possibly also with competitors?

- Are there sufficient readiness and internal resources to enter into intensive partnerships with technology companies and establish the necessary data flow?

- Is the company able to face up to the expected increasing competitive pressure in the industry due to new differentiation opportunities?

In order to make the transformation to IoT platform connectivity in the best possible way, the following success factors and preparatory steps can be derived from successful projects:

- Create a willingness within the company to address the topic of IoT platforms (Digital Mindset).

- Development of a platform strategy (Digital Strategy).

- Conducting an inventory of digital maturity (competences and resources related to IoT platforms, use of data, technologies used).

- Analysis of available options (suitable platforms, conceivable partners, possible data usage, desired services, available technologies, possible business models).

Machine manufacturers

The use of IoT platforms also offers great potential for machine manufacturers, especially in the following areas:

- Offer of service packages (servitization) instead of selling products

- Access to real-time data and influence on the production processes of customers

- Access to historical data sets that can be used for product development.

- Use of the digital twin for machine optimization (Digital Twin)

- Development of new pricing models that do not account for the purchase but the use of the machines

The connection to platforms also requires a not insignificant change in the organizational culture on the manufacturer side. The main challenges facing companies are:

- Are there the prerequisites and the willingness to shift value creation and sales shares from machine sales to digital services?

- Are pricing mechanisms and customers willing to pay for digital services in the business area clear?

- Can we meet the completely new know-how requirements compared to the previous core business?

Status and outlook

Recent figures from Germany show that 85% of potentially accessible machines are still unconnected, which shows the high potential of platform solutions. Not least because of the Corona pandemic and the strategic political initiatives, the “digitalization momentum” in the economy is currently very high6. This can be used to analyze the potential for using platform solutions and to seize opportunities.

[columns] [column size=”1/2″]

Industrial IoT-as-a-Service Solution

Siemens’ MindSphere is the leading industrial IoT-as-a-service solution that leverages advanced analytics capabilities and AI to implement IoT solutions from Edge to Cloud. MindSphere enables industrial companies of all sizes worldwide to connect their machines and physical infrastructure to the cloud and the Internet of Things. It uniquely simplifies the challenges of many industries in connectivity, data analysis and forecasting, as well as the development of their own applications and new business models, thus helping every company transform digitally. Built on Mendix’s application platform, MindSphere enables its users to quickly personalise IoT applications.

Siemens’ MindSphere is the leading industrial IoT-as-a-service solution that leverages advanced analytics capabilities and AI to implement IoT solutions from Edge to Cloud. MindSphere enables industrial companies of all sizes worldwide to connect their machines and physical infrastructure to the cloud and the Internet of Things. It uniquely simplifies the challenges of many industries in connectivity, data analysis and forecasting, as well as the development of their own applications and new business models, thus helping every company transform digitally. Built on Mendix’s application platform, MindSphere enables its users to quickly personalise IoT applications.

[/column] [column size=”1/2″]

Industrial Edge

The optimal use of data is becoming increasingly important for industry. Many companies have already recognized this and analyze data from machines and systems on industrial PCs with the help of their own software. While this brings valuable insights, it’s expensive and requires frequent manual updates to keep software, operating system, and cybersecurity up to date. With Industrial Edge from Siemens is simpler, more flexible, and more secure – for optimal data use in the field: Data can be captured and processed directly and securely on the machine, without latency, with its own software and a central system for management, deployment and updates. The Industrial Edge Management System is the central infrastructure that can manage all connected edge devices of any kind worldwide. Instead of having to apply updates and security patches on each device individually, centralized control is possible from a system that can be installed on-premises or in the cloud as needed.

[/column][/columns][:]