The European Commission’s Directorate General for Energy (DG ENER) recently organized a press trip focused on energy efficiency to showcase a number of innovative projects in or close to Vienna that highlight investments that help to decrease energy consumption. Such projects not only illustrate the benefits of saving energy – in terms of reducing energy bills and lowering our greenhouse gas emissions in the fight against climate change – but also serve as proof that actions can be taken in order to further diminish our dependence on energy imports, lessen air pollution, and, more broadly, improve our quality of life.

Geothermal and solar energy for historic residential buildings

Two residential blocks dating back to the mid-19th century underwent a major renovation with support from the Austrian government’s Climate and Energy Fund. The focus of the project was on the overall renovation of an urban block, which included a system of alternative energy supply extending across the individual plots. In this case, the renovation installed an energy generation plant based on the use of geothermal and solar energy. “We prefer to name it ‘restructuring’, because it is much more than simply renovation”, said architect Johannes Zeininger, who coordinated the project. New spaces were added, and new forms of utilisation were made possible. For comfort and efficiency, floor heating and ceiling panels were used. Water is warmed with PV thermal panels and then injected through pipelines underground. 18 130-meter-deep holes were dug for storing heat by increasing the soil temperature by 1-3 degrees. “This is geothermal 2.0”, highlighted Johannes Zeininger, referring to the fact that the geothermal source is “created”, not just harnessed.

The project included comprehensive conservation and improvement measures. The overall investment was 2 million euros, while the energy-related costs were around 300,000 euros.

50% reduction in energy needs for the Austrian Parliament Building

The Austrian federal parliament building was reopened on January 2023, after four years and a half of general renovation and a 422 million euro investment. Taking into account the historic building fabric, special emphasis was placed on thermal renovation, energy efficiency, sustainability, and accessibility. Using roof-top PVs was not an option for two main reasons. First, the calculated efficiency of the photovoltaic equipment was not high enough, and second, the people prefer not to impact the historic look of the building.

Embracing the latest technology and design – from new windows to modern LED lighting technology – the changes are forecast to reduce the building’s energy requirements by up to 60 percent, from 120 kWh pe square metre to 40 kWh, while also improving the comfort and quality of working conditions.

Density is the best thing for energy efficiency

Vienna already has the lowest energy consumption per capita in Austria and the highest decrease in total final energy consumption compared to 2005, according to Urban Innovation Vienna, the climate and innovation agency of the City of Vienna. “Density is the best thing for energy efficiency”, said Michael Cerveny, responsible for energy issues. Because of the large number of people living in the city, Vienna‘s greenhouse gas emissions (emissions from buildings, traffic, and non-ETS-production) per capita or per euro are by far the lowest in Austria.

At present, one-third of all trips within Vienna are „muscle-driven“, walking or by bicycle. 30% of the trips in the city are „electric“, based on e-cars, but especially on an extended network of trams. People are encouraged to use public transportation by means of a 365 euros per year ticket (1 euro per day), entitling its owner to use it for an unlimited number of journeys on the underground, tram, and bus (except for special express bus lines), the suburban trains (ÖBB) and the Badner Bahn (to Vösendorf-Siebenhirten).

While Vienna has the lowest per-capita energy consumption for heating among the Austrian cities, a solution is still to be found for replacing natural gas as the main resource. In Vienna, there are around 600,000 buildings using gas for heating, and 80% of them use a gas boiler for each apartment.

Waste heat from data centre to heat a hospital

The private company Interxion is in charge of running the enormous server complex on Brünner Straße. Behind the façade of a simple office building, a network of almost 120,000 servers is hidden on thousands of square metres. These need a constant temperature and must be permanently cooled so as not to overheat.

After a 3.5 million euro investment, Wien Energie GmbH is now using this waste heat and supplying it to the neighbouring Floridsdorf Clinic. The project has allowed Wien Energie GmbH to decrease the use of gas for heating and power generation, which has also reduced its CO2 footprint.

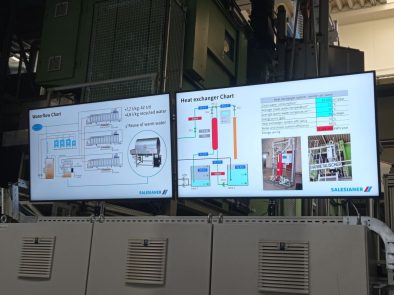

Sustainable solutions for laundry facilities

The SALESIANER Group is an Austrian family-owned company that has been offering top-quality laundry and textile rental services for over 100 years. With 30 locations in the CEE region and 3.000 employees, the SALESIANER Group is a large consumer of natural gas (over 100 GWh in 2022) and electricity (16,8 GWh).

The consumption is derived mainly from washing linen and containers (steam and electricity) and drying / ironing (gas/steam and electricity).

In order to get energy saving and efficiency, actions were taken to optimise the steam boiler and processes (steam boiler sizes and efficiencies, reduce losses in pipes), and heat recovery. Wastewater and exhaust air were used for preheating fresh water, and the pressing time was optimised in a program that is approximately 70% implemented and will continue.

SALESIANER was the first Austrian company to achieve the ecolabel for rental textiles, and it has been awarded a renowned state prize for textile recycling.

A 30% more energy-efficient bakery

Ankerbrot has invested more than 30 million euros in state-of-the-art technologies, which allowed its new product lines at the industrial bakery’s new location to adjust the baking process specifically to their utilisation during production. As a result, the new thermal oil ovens ensure energy savings of 50%, which is more than 5.6 million kWh per year compared to the previous conveyor ovens. Regarding carbon emissions, it is estimated that more than 1,400 tons CO2 a year can be saved with the new technology.

Additional energy-saving improvements include using free cooling, optimizing the process in the fermentation cabinets, and using efficient NH3 cooling systems with low Global Warming Potential (GWP). The latest technology also includes waste heat recovery and the use of a 1 MWp photovoltaic system.