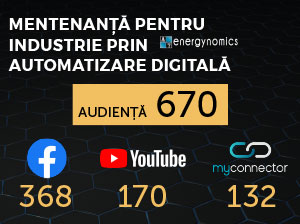

On June 4, Energynomics organized its second online conference dedicated to maintenance of power utilization systems, focusing on the most efficient solutions and approaches. 5 invited guests presented some examples of good practices and expressed their opinions on the most important topics from the perspective of industrial maintenance in Romania, including the quality of specialized workforce, the transition from post-factum repairs to predictive technologies through IT solutions that come with intervention recommendations before accidental interruption of production flows. The conference was broadcast live online and was watched by around 700 people.

From Big Data to Smart Data

“We have executed two pure maintenance projects in the Middle East,” said Cristian Pirvulescu, CEO of ENEVO Group. “Our approach starts with elements of monitoring and automation, because we believe there is no maintenance without data, and here we have to go from Big Data to Smart Data.”

ENEVO Group is currently carrying out one of the largest projects in Saudi Arabia, a station that will supply power to a large oil field. “Together with colleagues from Siemens, we carried out a very important work in one of the largest steel mills in the Middle East, and in Romania we are now working, using Schneider platforms, for the automation project of the 230 MW hydro plant Stejaru. We take care of everything related to automation system and hydro-arrangement dispatcher, which is to be connected with the control systems”, said Cristian Pîrvulescu.

“Statistics tell us that the industry loses about $ 20 billion annually due to unplanned shutdowns, which is a huge figure, about 5% of global production,” he said. ENEVO aims to change the way this topic is approached – to move from reactive maintenance to preventive maintenance: “globally only 22% of the data collected are well enough organized to be analyzed, and only 5% of them are actually analyzed”. Enevo has started to promote a new type of service for the local market – a series of products, services and platforms to monitor facilities and optimize interventions. “Especially in the industry, we are facing over-maintenance of critical equipment, while companies tend to forget that ancillary equipment is just as important.”

The biggest problem is the lack of specialists

“Romanian companies do not pay much attention to maintenance”, said Daniel Barciuc, Director of Digital Industries Siemens Romania. However, some companies have outsourced their maintenance services and this is a growing trend.

- Gabriel Tache

- Cristian Pîrvulescu

- Liviu Drăgoi

- Lauru Bădiță

- Daniel Barciuc

- Gabriel Avăcăriței

“Each solution is unique. There are solutions that can be generalized, too, such as addressing the losses in the distribution grids. But there are no general solutions for a factory, for example. “In every situation, the answer depends on the existing equipment. Many plant managers want to do automation, but they do not take data collection equipment into account. Many industry leaders forget about overhauls and do not analyze the equipment they already have (equipment audits). We have the possibility to perform such audits”, Barcius also said, highlighting that an equipment that stops working can mean very high losses.

DOWNLOAD THE PRESENTATION OF DANIEL BARCIUC

Siemens has been in Romania for almost 112 years, now with four factories and two research centers, and also the sales, service and projects center in Bucharest. For staff training, Siemens has two training centers, one in Bucharest and one in Cluj. In Romania, “we have a big problem with the labor force – one reason is specializing people getting old; another results from the fact that specialists in the field are not paid very well. ”

Digital platform for effective interventions

“Collecting data is not enough, you must also act in the field to perform preventive maintenance… Each equipment must be cleaned and properly maintained, otherwise there are energy losses,” said Lauru Bădiță, Country Manager Romania, Photon Energy.

DOWNLOAD THE PRESENTATION OF LAURU BĂDIȚĂ

Photon Energy has 120 employees and operates in 10 countries, providing operation and maintenance services for solar parks totaling more than 300 MW in installed capacity. The main markets are in the Czech Republic, Slovakia and Australia; in Romania, Photon Energy has 16MW in operation and maintenance. “We focus on preventive maintenance, monitoring and corrective maintenance interventions – everything related to proper operation and prevention for power generation. We have our own monitoring platform, with which we can take over the data from the suppliers in the park, and through which we can monitor all the events and production in a solar park”, said Lauru Bădiță.

Financial gains from reduced downtime

“Service is a strategic lever that improves customer satisfaction and loyalty, with implications in increased competitiveness for our partners. Reducing downtime, equipment unavailability, is essential, it means financial gains”, said Gabriel Tache, Country Sales Manager, Eaton Electric.

The company is part of Eaton Corporation, which is headquartered in Dublin, Ireland, but operates worldwide. “We are present in 175 countries with over 100,000 employees. Eaton has in Romania both sales and production units in the north of the country, in Baia Mare and Arad. In total, we have over 2,500 employees in Romania”.

DOWNLOAD THE PRESENTATION OF GABRIEL TACHE

The company is part of Eaton Corporation, which is headquartered in Dublin, Ireland, but operates worldwide. “We are present in 175 countries with over 100,000 employees. Eaton has in Romania both sales and production units in the north of the country, in Baia Mare and Arad. In total, we have over 2,500 employees in Romania”.

Downtime costs are crucial in the investment decision to modernize maintenance systems, said Gabriel Tache. “Ideally, digitalized servicing solutions should be introduced from commissioning in order to ensure continuity in power supply. When the equipment is already in operation in the plant, we act step by step; we start from the identification of the critical areas for the functioning of the unit, we bring it in the 21st century, after which we move on to the next critical area. It is crucial how high the costs of downtime are, the costs that the factory pays for the period when the activity is interrupted.”

Aveva solutions for predictive maintenance

According to a study quoted by Liviu Drăgoi, Sales Manager of ACE Industrial Software Solutions, only 18% of defects that occur in industrial assets are caused by the age of the equipment. For them, preventive maintenance programs and repairs are valid options. The remaining 82% are accidental accidents, unrelated to the age of the affected equipment. For them, monitoring and predictive technologies are the most effective approaches.

“If you manage to reduce this 82% share, you get a huge margin for improving the business performance. Reactive maintenance is to be avoided, as it causes unwanted expenses”, considers Liviu Drăgoi.

The predictive maintenance solution proposed by AVEVA is based on data taken from equipment and stored over time, but also on internal libraries. “It is the type of maintenance that is based on the data taken over and stored; the AVEVA solution generates scenarios for predicted evolution that, compared to the data received in real time, highlight the anomalies before they turn into defects.”

DOWNLOAD THE PRESENTATION OF LIVIU DRĂGOI

ACE Industrial Software Solutions is a new company, launched in 2019, as an exclusive distributor of Aveva IT solutions, starting “from Aveva’s desire to stay close to its customers, and materialized in an authorized Aveva center, with authorized trainers.”

Aveva is a world leader in providing industrial software, with solutions deployed in over 100,000 sites, in companies in all industries. “Aveva has more than 4,000 people on its team and processes a huge volume of data. Of the first six main players in the oil and gas area, five use Aveva solutions”, said Liviu Drăgoi, presenting the company’s portfolio.

The conference “Maintenance for industry through digital automation” was organized by Energynomics with the support of our partners ACE Industrial Software Solutions, Eaton Electric, ENEVO Group and Photon Energy.

132 people registered in the MyConnector platform for entering the dialogue. They came from organizations such as ABB, ACE Industrial Software Solutions, AEE / SAMER, Aktron, Alwo Therm srl, ANMB, Apa Canal Sibiu, Arc Electronic, Autoliv, AVIVA, BBTR, BEIA, Box2M, Business France Romania, CCC KRONSTADT, CELCO, CLASIC MEX, Cluj Innovation Park, CMT Elec, Conpet, East Trade, Eaton Electric, ECI PROJECTS, EDPR, EDS, EFdeN, Electrica Furnizare SA, Electrotehnica Consult SRL, Elektra Renewable Support S.R.L., EMERSON PROCESS MANAGEMENT ROMANIA SRL, Energobit, ENERGOM, ENGIE, EPG, Ewind, Friesland Campina, Garrett Advancing Motion, GC, Global TECH, GLOBEMA, Growth, H Grup IT, Helukabel Romania, Hidroelectrica, Hitachi Europe Ltd., HS BACO PANELS, ICI Bucharest, Institutul National de Cercetare-Dezvoltare in Informatica, Institutul Național de Cercetare-Dezvoltare pentru Tehnologii Izotopice și Moleculare Cluj, KFactory, Klarwin, MG, OMV Petrom, PREFAB SA, QEtics, RO, ROM Devices, SC KULZER SRL, SC SPOTING SA, Schneider Electric, Siemens, Smart Factor, Stabilus Romania, STEINEL, Technosam SRL, Teltonika, TIAB SA, TPA Group, Transelectrica, Transgaz, Transiris, Unilever, Universum, UPRUC CTR SA FAGARAS, UTCN, Vodafone Romania Technologies.

132 people registered in the MyConnector platform for entering the dialogue. They came from organizations such as ABB, ACE Industrial Software Solutions, AEE / SAMER, Aktron, Alwo Therm srl, ANMB, Apa Canal Sibiu, Arc Electronic, Autoliv, AVIVA, BBTR, BEIA, Box2M, Business France Romania, CCC KRONSTADT, CELCO, CLASIC MEX, Cluj Innovation Park, CMT Elec, Conpet, East Trade, Eaton Electric, ECI PROJECTS, EDPR, EDS, EFdeN, Electrica Furnizare SA, Electrotehnica Consult SRL, Elektra Renewable Support S.R.L., EMERSON PROCESS MANAGEMENT ROMANIA SRL, Energobit, ENERGOM, ENGIE, EPG, Ewind, Friesland Campina, Garrett Advancing Motion, GC, Global TECH, GLOBEMA, Growth, H Grup IT, Helukabel Romania, Hidroelectrica, Hitachi Europe Ltd., HS BACO PANELS, ICI Bucharest, Institutul National de Cercetare-Dezvoltare in Informatica, Institutul Național de Cercetare-Dezvoltare pentru Tehnologii Izotopice și Moleculare Cluj, KFactory, Klarwin, MG, OMV Petrom, PREFAB SA, QEtics, RO, ROM Devices, SC KULZER SRL, SC SPOTING SA, Schneider Electric, Siemens, Smart Factor, Stabilus Romania, STEINEL, Technosam SRL, Teltonika, TIAB SA, TPA Group, Transelectrica, Transgaz, Transiris, Unilever, Universum, UPRUC CTR SA FAGARAS, UTCN, Vodafone Romania Technologies.